Double shield TBMs to take on Norwegian hard rock

11-09-2015

The four new TBMs being built by Herrenknecht to excavate the twin tube Follo Line high-speed railway tunnel in Norway are 9.96m diameter and specified as double-shield machines.

Ordered by the construction JV Acciona/Ghella (AGJV) under a machine supply contract signed in March 2015, the four TBMs will work through hard tonalitic-granite of up to 350MPa in UCS and will erect the specified precast concrete segmental lining as they progress. The machines will work in pairs and in opposite directions from the central Åsland working access adit to complete the total 37km of hard rock excavation to complete the parallel 18.5km long tubes.

“The double shield concept with a one-pass precast concrete segmental lining is specified by the client in the contract and advance will be carried out as far as possible in the simultaneous excavation and ring building mode,” explained Giovanni Giacomin, Tunnelling Director for construction partner Ghella. “Nevertheless,” he added, “the overall production will be affected by the many associated operations including regular probe drilling of 4 to 8 holes of 35m long every 30m of advance, core drilling, and extensive pre-grouting when required.”

For the AGJV, the TBM drives for the Oslo-Ski Follo Line tunnels is the next experience with Herrenknecht double shield machines. The Norwegian project follows the JV’s successful completion, with local JV partner BMD, of the Legacy Way twin tube highway tunnel project in Brisbane in 2013 using two 12.4m diameter double shield Herrenknecht TBMs.

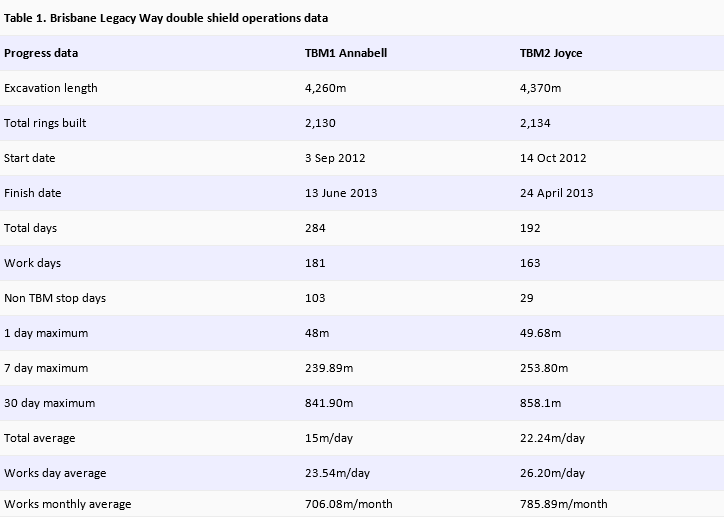

“In Brisbane we used the TBMs in classic double-shield mode for the full length of each 4.3km long tube and this resulted in exceptional progress rates,” said Giacomin. “We achieved rates of up to 850m/month per machine, which was something not possible with single shield machines erecting a precast segmental lining.”

The two machines in Brisbane were the remanufactured double shields used first for the twin-tube Clem 7 highway tunnel under the city’s Brisbane River. For the Clem 7 project, efforts to control high water inflows prevented optimal double-shield excavation and simultaneous installation of the segmental lining. For the following Legacy Way project, the details of the excavation record illustrates the potential of double-shields to maximise progress rates (Table 1).

The first TBM for the Follo Line project is currently under manufacture at the Herrenknecht workshops at Schwanau in Germany and is scheduled for factory test acceptance by the end of February 2016. The second TBM is programmed to be ready by end of March. The third and fourth TBMs are to be ready by end of May, beginning of June.

“We will take delivery of the first two machines during Spring of next year (2016) and have the first one assembled and ready for launch by September,” Giacomin told TunnelTalk in a telephone interview. “Ahead of that we have about 10 months of drill+blast work to complete, to excavate approximately 300,000m3 of rock including the large TBM assembly and working chamber on the alignment of the main TBM tunnels. We took possession of the central access Åsland working site in June this year (2015) and made a very effective and efficient start on the drill+blast works with our local subcontractor AF Gruppen. To date, 30% of the total drill+blast excavation is completed and the chamber excavation is expected to be completed by May 2016.”

Under a separate early works contract, AF Gruppen completed the 1km long tunnel from Åsland to the location of the TBM assembly chamber.

To prepare for main tunnel drives, AGJV will establish the site factory and start casting the segments of the precast concrete segmental lining of the TBM tunnels in March 2016.

Valued at about US$1.2 billion, the EPC (engineering, procurement construction) Follo Line contract with AGJV is the largest contract awarded to date by Norway’s National Rail Administration – Jernbaneverket. Services on the new line, that includes four other large EPC excavation and station upgrade contracts, are scheduled to start by the end of 2021.

October 2015, Shani Wallis, TunnelTalk

References

- Brisbane’s Northern Link Legacy Way plan of attack – TunnelTalk, September 2010

- Rapid excavation breaks through in Brisbane – TunnelTalk, April 2013

- Final breakthrough for Brisbane traffic link – TunnelTalk, June 2013

- Acciona/Ghella selected for Follo Line TBM tunnel – TunnelTalk, March 2015